Last Updated on

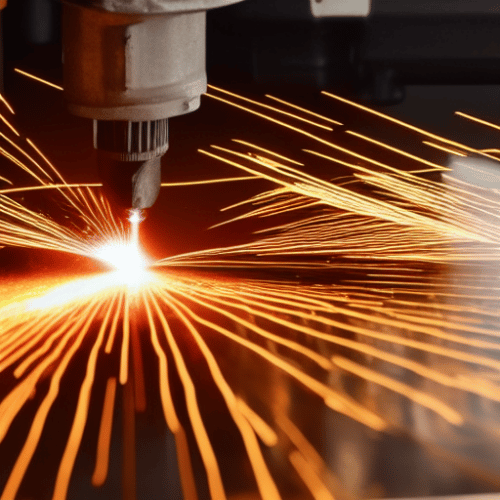

A plasma cutter is a versatile tool that generates high heat energy, which helps you cut various types of metals, materials, and equipment that have different thicknesses. Such cutters emit a plasma jet that has high temperatures, which range from 6,000° to 20,000°, producing enough energy to break down metal ions and cut through a certain workpiece.

Since this tool is made from a rather complicated technology, many find it quite hard to wrap their heads around this tool. In this post, we are going to show you how plasma cutters work. Let’s get right into it.

What Is Plasma?

Before we dive deeper into this, we are going to give you an insight into the main component of this tool – plasma.

While matter is available in three different states – gas, solid, and liquid – it can be modified under certain conditions until it gets to the fourth state. The fourth state of matter is called plasma and can be used in different tools such as the plasma cutter machine to do some plasma cutting. You can cut heavy materials such as stainless steel and mild steel. A plasma cutter machine can also cut equipment that has varying thickness levels.

In the presence of energy, matter can be easily modified to different forms and states.

For instance, gases in the air can be exposed to high-heat energy levels and then ionized to produce plasma. Apart from that, plasma generates a lot of heat energy, making it easier to cut material.

Components of a Plasma Cutter Machine

Plasma Arc

This is the plasma matter that cuts through a certain metal, giving it a smooth edge.

Nozzle

This is the part that directs the plasma arc to the right spot, making it easier to cut a certain workpiece through the plasma cutting technique. It is found in the torch tip. Nozzles that have a huge diameter are good for gouging metals and other materials. On the other hand, nozzles that have a small diameter are effective in precision plasma cutting.

Swirl Ring

A swirl ring recirculates gas and air around the plasma arc during the plasma arc cutting process. Compressed air has to be swirled to minimize the effects of ions on the plasma cutter. Since gas passes through the nozzle of the cutter, it might degrade the nozzle if it’s not in an optimum state.

The ring keeps the gas at an optimum state by recirculating some of the compressed air, saving the nozzle from the effects of harsh gas molecules.

Shield Cap

A shield cap safeguards other consumables from hot molten metal bits and the sparks produced during the plasma cutting process. It covers multiple parts.

Plasma Torch

This is the part that aligns the whole unit and houses other parts. Examples of such parts, also known as consumable parts, include swirl rings, nozzles, and electrodes.

Power Supply

A plasma cutter machine comes with a power supply, which changes AC to DC. Direct current supplies enough power to the plasma cutter, making it easier to produce a steady arc.

Arc Starting Console

As the name hints, the arc starting console is the part that triggers the production of the plasma arc. It causes the plasma to be generated at a steady rate.

It generates an AC voltage, which is strong enough to light up a spark in the torch, producing a plasma arc. Most plasma cutters use an arc starting console to speed up the whole process. They can generate a high-frequency spark in a short period of time.

Plasma Electrode

The plasma electrode conducts electricity to the torch, generating power for the plasma arc. Apart from that, it also ionizes plasma gas with some of the power that it generates.

Bevel Head

This is a unique part, which is mostly found in CNC (Computer Numerical Control) cutters. CNC cutting is a unique cutting technique that uses computers to minimize manual errors and automate the whole process. A bevel head is a special part that makes angled plasma cuts and straight cuts automatically.

Types of Plasma Cutters and Units

Since different plasma cutters have varying cut quality, we are going to show you the different types of plasma cutters.

Conventional Plasma Cutter Machines

Conventional plasma cutter machines often produce different shapes of plasma arcs based on the performance of the nozzle, making it easier for you to work on a certain cutting area.

Precision Plasma Systems

As the name hints, these systems are quite accurate and precise. Such machines have a special design that generates a plasma that gives you quality cuts. Not to mention, some additional parts are added to the whole system of such units to shape the plasma. Plus, the consumable parts and the torch have a unique design. A precision plasma cutter helps you find the most accurate way to cut metals and other hard materials.

How Do Plasma Cutters Typically Work?

Basic Principle of the Plasma Arc Cutting Process

While plasma cutters are available in different designs and types, they work under the same principle using the arc cutting process.

In most models, an electric arc comes into contact with the gas that flows through a constricted plasma torch space. Examples of such gases include oxygen, nitrogen, argon, and shop air.

Once the electric arc comes into contact with one of those gases inside the torch, the temperature will start rising gradually. After a certain point, the gas will change its state from a gaseous state to plasma. Plasma cutters are used can be used to perform different DIY tasks such as welding tasks.

How Different Cutters Work

Since plasma cutters are available in different designs, we are going to show you how each cutter works in detail.

Handheld Plasma Cutter

Just as the name hints, a handheld plasma cutter has a unique shape that lets you grasp it while you are working on different metals.

The nozzle and the electrode might touch each other if the whole unit is off. Once you press the trigger, direct current (DC) voltage will flow from the power supply to the plasma cutting torch.

After that, the plasma gas will start flowing into the plasma torch, building up pressure gradually.

The pressure will keep on building until it becomes strong enough to break the contact between the electrode and the nozzle, separating those two parts.

As a result, an electrical spark will be produced. It will heat up the gas to generate a jet of plasma or a cutting plasma flame. The flow of the DC voltage will change from its initial circuit path to a new circuit path. The circuit path enhances the performance of the cutter.

Precision Plasma Cutter

Unlike a handheld cutter, the nozzle and the electrode of a precision cutter do not come into contact. Those two parts are separated by a swirl ring.

Once the plasma cutter is powered, current flows through the consumables. It will trigger the release of the plasma gas.

Afterwards, the arc starting console will produce a spark that will ionize the gas (nitrogen, argon, or oxygen) and create a plasma jet. The gas will also be ionized to an electrically conductive state with a high-frequency spark.

Conclusion- Use a Cutter for Specialized Tasks

How do plasma cutters work? Well, a plasma cutter relies on different gases to produce a plasma jet, cutting a metal within a short period of time. A plasma jet produces high heat energy, which is quite effective in breaking down the ions of metal, making it possible to cut through a metal surface quite easily. Plus, a plasma cutter can cut metal in a straight line within a short period of time. Once the jet comes into contact with a metallic workpiece, it produces high-quality cuts, giving you smooth, even, and attractive edges.

Ian loves everything that revolves around the home improvement niche. He loves trying out new home appliances. He has also handled a lot of equipment and has a lot of insight. Plus, he’s worked on various home improvement projects that became a success.

If Ian isn’t busy working on his latest project, you can find him reading up about another one!