Last Updated on

Plasma cutters are products of advanced technology that make it easier for you to make different cuts on metals. Additionally, plasma cutters come in a variety of types and designs and can give you a different way to cut a wide range of materials. Plasma cutters can handle a wide range of metals, such as mild steel, aluminium, and stainless steel.

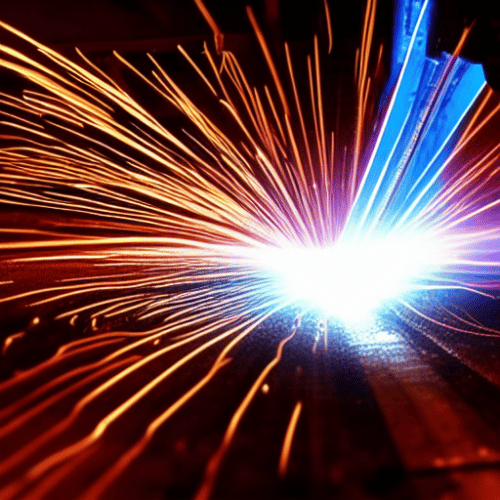

Whether you are planning to cut a thick metal or a thin metal sheet, a plasma cutter machine produces enough power to cut through different thicknesses. Also, such machines are supplied with high-voltage electricity that produces electrically conductive plasma.

Now, that’s just the tip of the iceberg; a plasma cutter system has tons of uses and can be used in various industries to complete a lot of tasks and projects. In this post, we are going to take you through exactly what are plasma cutters used for and the applications of this precision tool.

Uses

Contractor Works

Many plasma cutters are portable because of their compact designs, making it simple to transport them from one location to another. Also, plasma cutters are accurate in cutting different equipment to the exact measurements. Whether you are working on a thick or thin workpiece, a plasma cutter will get the work done.

Furthermore, you can cut plumbing fittings and steel metal pipes using a handheld plasma cutter. It emits a jet of plasma that passes through conductive metals, cutting different materials in a straight line. Plus, you can guide the nozzle based on your preferences to cut through a certain path.

Moreover, such tools can produce smooth pipe edges, making it easier for you to join two or more pipes.

Plasma Cutting In Artwork

Plasma cutters, especially precision plasma systems, can create a fine plasma arc, which is quite effective in detailing. Thanks to this, artists can use plasma cutters to add more details to metallic art pieces through the plasma cutting technique.

Furthermore, plasma cutters can help you incorporate fine lines into a piece of art through the plasma arc-cutting technique. It accurately cuts a piece of metal without distorting the edges, producing clean and quality edges on a certain workpiece. Moreover, plasma cutters have a fine cut width that can be used to style up artwork pieces.

A plasma cutter makes it easier for you to see the surface that you are working on, improving your accuracy. Many plasma cutters come with a lightweight plasma torch, which can be easily moved as you are working on a metallic piece of art.

As if that’s enough, some plasma cutters may offer you special consumable parts, which are designed to cut metallic equipment more precisely than other cutters.

While a plasma cutter can shape metal into a piece of art, it can also help you produce a stylish metal template that can be used to generate even more art.

Computer Numerical Control (CNC) Plasma Cutting

As the name hints, this is an automated plasma-cutting method that incorporates advanced computer technology to cut material. It was designed to accurately cut various metallic equipment and minimize manual errors. It is mainly used in industrial applications to work on different products.

In this method, the plasma torch will be controlled by automatic motors and gears while cutting tubes, metal chunks, and metal sheets.

Additionally, computer numerical control plasma cutting techniques can be grouped into two categories; 3D or 2D computer numerical control plasma cutting.

The two-dimensional CNC plasma cutting method is mainly used to make normal and precise cuts on flat metal sheets. The electrically conductive plasma arc comes into contact with the sheet material at a 90° angle, producing high-quality, smooth edges.

In the three-dimensional CNC plasma cutting method, the plasma cutting torch can be tilted at a certain angle while cutting sheet metal. As a result, the metal surface will have a 3D effect.

The computer numerical cutting CNC method can be used to engrave different letters on metal surfaces in a stylish manner. In addition, different cutting designs can also be incorporated into metals.

Examples of such designs include profiled holes, countersunk holes, and chamfer edges.

Repairing

Well, different types of metals might become damaged after a certain time. Some deformed metal parts have to be cut during the repair process. To get effective results, you have to cut those parts using a plasma cutter. For starters, a plasma cutter produces clean edges, making it easier for you to join two pieces of metal. It can cut steel, aluminium, or any other metal.

The plasma-cutting technique also speeds up the repair process. Instead of wasting time with other cutting tools, use a plasma cutter to make the work easier. Also, plasma cutters do not produce a lot of debris while cutting metal parts.

Other cutting tools might make metal bits start chipping off from the metal surface. However, a plasma torch is quite effective in cutting multiple metals without affecting the edge and the surface. It can also make cuts on equipment that have varying thicknesses.

Advantages of Using Plasma Cutters in Different Projects

Here are the advantages of using a plasma cutter system to work on industrial items and home appliance items:

Quick in Cutting Different Metals (High Cutting Speed)

Plasma cutters can emit a cutting plasma jet with high heat energy levels, breaking down metal ions quickly. A plasma arc might have a temperature that ranges from 20,000°c to 28,000°C, depending on the type of plasma cutter. The arc-cutting method works very fast, making it easier for you to cut a workpiece.

Cuts Various Metals

Plasma cutters are also effective in cutting materials made from different types of metals. Examples of such metals include copper, steel, titanium, metal alloys, and iron. Due to this, such cutters can help you work on different projects and tasks.

Safer Than Other Tools

Since most cutters relied on inert gases and compressed cutting gas to produce a plasma arc, they are much safer than tools that use oxygen to generate heat. Once the compressed air passes through the electrode, it gets ionized. After a certain period, the pressure builds up, and then the gas is ionized completely to emit a plasma jet that has high heat energy. Oxygen is a gas that speeds up combustion, increasing the risk of accidental ignitions. Oxygen-cutting tools can also cause explosions if they are not used properly.

On the other hand, inert gases cannot cause accidental combustions or explosions like oxygen gas. When it comes to safety, plasma cutters perform really well.

Low Maintenance Cost

While some of the consumable parts might wear off after being exposed to high temperatures and molten metal, they can be easily replaced at an affordable cost. Not to mention, such parts might take a long time to wear off completely. Plus, multiple plasma cutters come with a special part for protecting other parts from the effects of harsh conditions. An example of such a part is the shield cap.

Get a Plasma Cutter

And there you have it, everything you need to know about the applications of plasma cutters. Plasma cutters can be used in construction projects, industrial projects, and other DIY projects. Once the cutting plasma jet gets hot enough, it can cut through the hardest metals.

Moreover, most plasma cutters feature a highly durable nozzle that can withstand hot temperatures. Plus, they have durable torches that can go for a long time without getting affected by extreme temperatures. Such torches are also effective in holding other consumables.

Ian loves everything that revolves around the home improvement niche. He loves trying out new home appliances. He has also handled a lot of equipment and has a lot of insight. Plus, he’s worked on various home improvement projects that became a success.

If Ian isn’t busy working on his latest project, you can find him reading up about another one!